Manufacturing

Building the Industry's Best

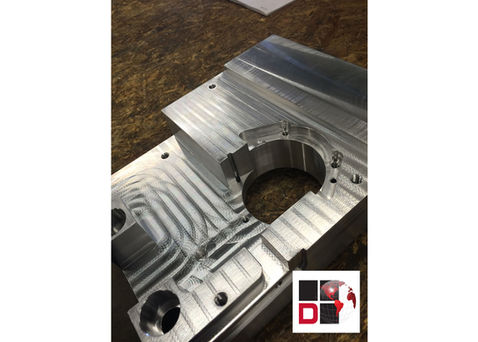

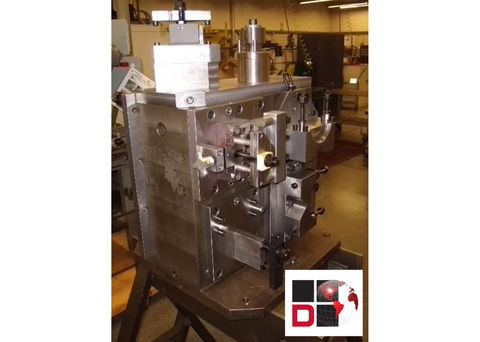

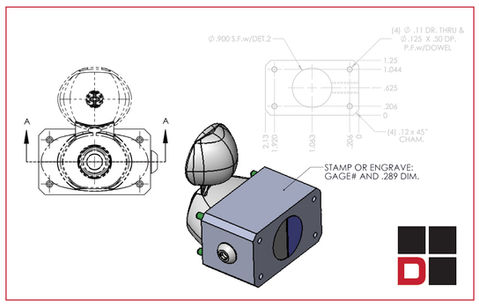

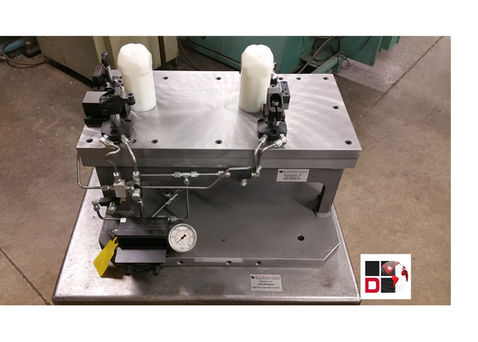

Diversified Design & Manufacturing builds the industry’s best gages, fixtures, components, tooling and manufactured parts. Our journeyman toolmakers employ a wide range of methods and machines to process short-run production parts…..on-time, on-budget and ready-to-perform.

All of our systems are custom designed and engineered to streamline manufacturing operations, increase productivity, improve product quality and reduce overall costs. We’ll take on your biggest challenges – even in small quantities.

-

Plastic Mold Tooling (Injection, Compression, Extrusion, Blow, Dip, Thermoforming, etc.)

-

Mold Bases and Components

-

Metal Dies and Castings (Investment, Continuous, Resin, etc.)

-

Metal Stamping

-

Forgings (Rolling, Extrusion, Pressing, Bending, Shearing)

-

Standard Machining (3D Milling, Turning, Drilling, Tapping, Grinding, Finishing, etc.)

-

Gear Machining and Gear Box Making

-

Additive Manufacturing (3D Printing, Laser, etc.)

Quality Control

At Diversified Design and Manufacturing, quality is our commitment. We live it daily through integrity, insight and teamwork.

We assure inspection on every product we produce and strive to achieve industry leading standards. We validate and deliver these standards daily and build lasting customer relationships based on this principle. Our relentless commitment quality includes our AS-9100 certification.